Behind the Dryer: What to Check

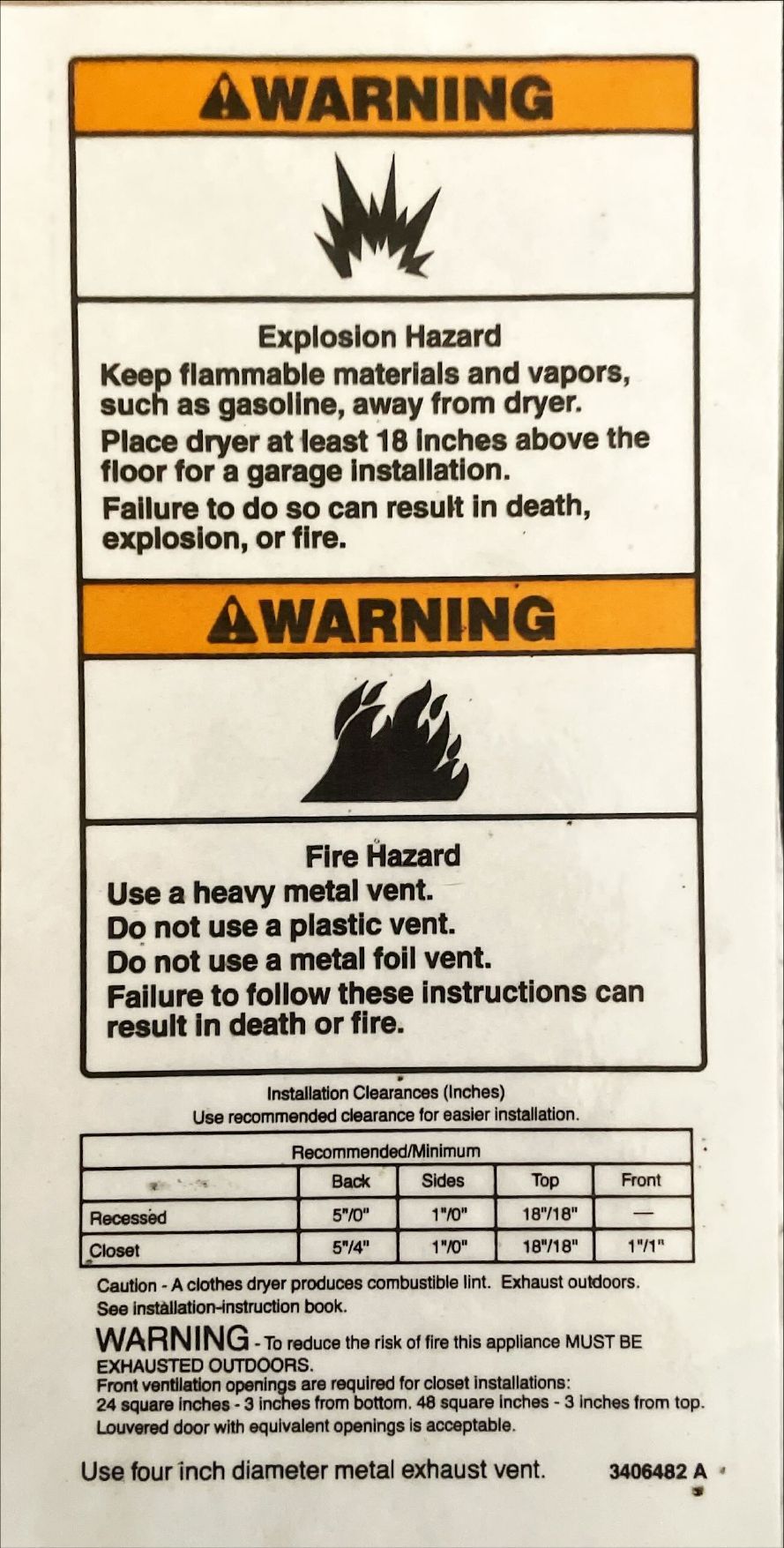

Transition Duct Materials

- Rigid or semi-rigid heavy metal only

- (NO plastic or foil accordion-style)

- UL-listed for dryer use

- Transition no more than 8 feet.

Connection Method

- No screws (they trap lint)

- Foil-backed metal tape (UL 181) used to seal joints

- Secure with hose clamps or approved connectors

Airflow Direction

- Transition duct should not kink or crush

- Male ends of duct point in the direction of airflow

- Do not use screws or screens in ducts or vents

In-Wall or Ceiling Exhaust Duct

Construction Material

- Rigid galvanized steel or aluminum (28-gauge minimum)

- Absolutely no PVC or plastic

Route and Length

- Transition should be no more 8 feet

- As short and straight as possible

- Minimal turns for better airflow

- Add clean-out access for long or hidden runs

Outdoor Vent Damper (Exterior)

- Has a backdraft damper

- NO screens

- No bird nest or bee hives

- Minimum 12” above ground

- Points downward to prevent water/rain entry

DO NOT USE

❌ No duct screws

❌ No plastic, vinyl, or foil ducts

❌ No shared exhaust systems

❌ No concealed flexible ducts in walls or ceilings

❌ Do not use duct tape (it degrades with heat)

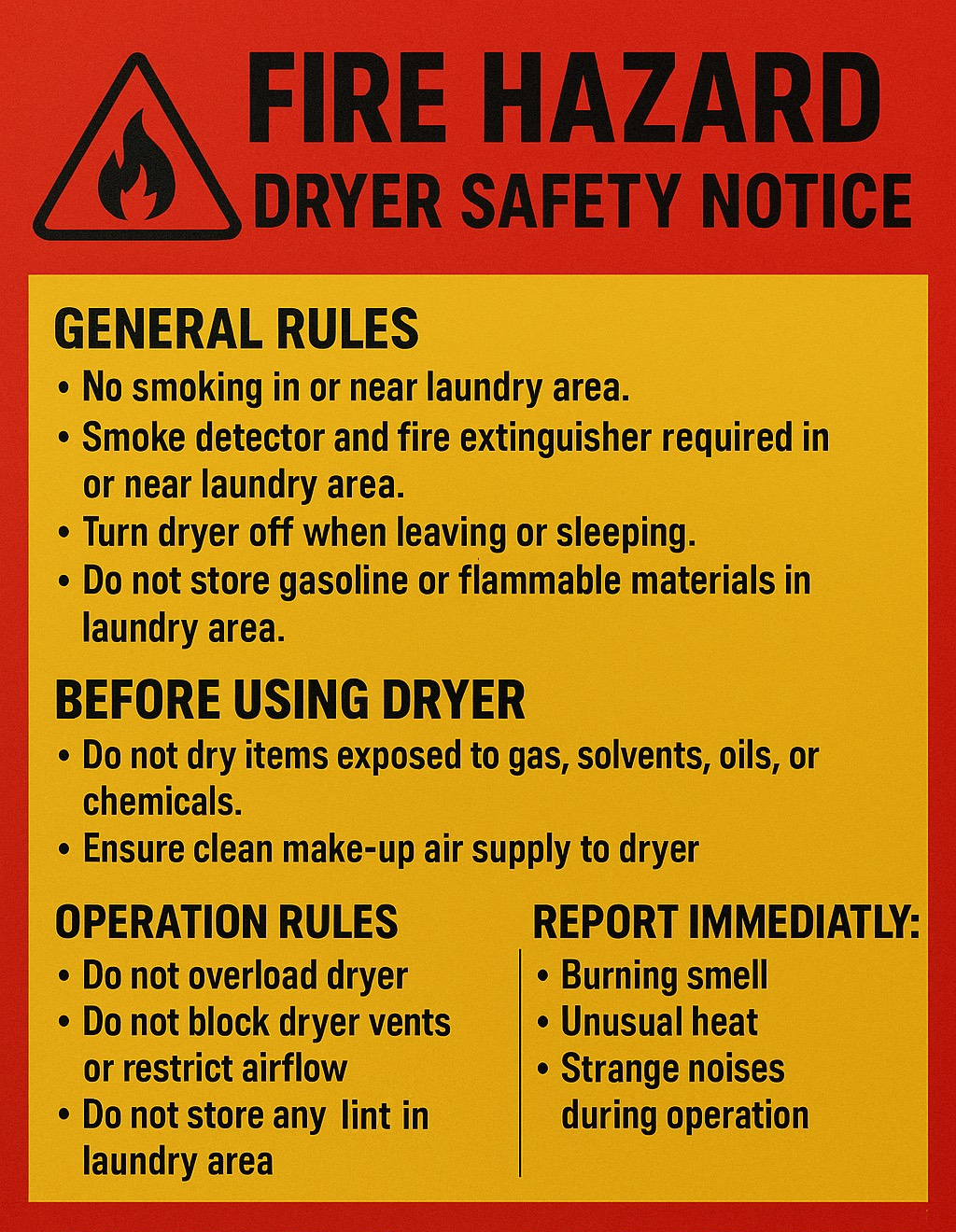

Safety for Condos, Apartments, Townhouses

If the dryer is far from an exterior wall, ensure:

- Clean-out transition duct behind dryer

- Do not use screws

- Used only metal foil heat tape

- Have a smoke detector and a fire extinguisher readily available

- Check for carbon monoxide detectors if a gas dryer is used

Maintenance & Inspection

- Clean the dryer vent system at least once a year

- If using a booster fan, inspect every 6 months

- Check the interior of transition duct for lint buildup

- Have system inspected after renovations or new appliance installs