To ensure compliance and fire safety for dryer vent systems:

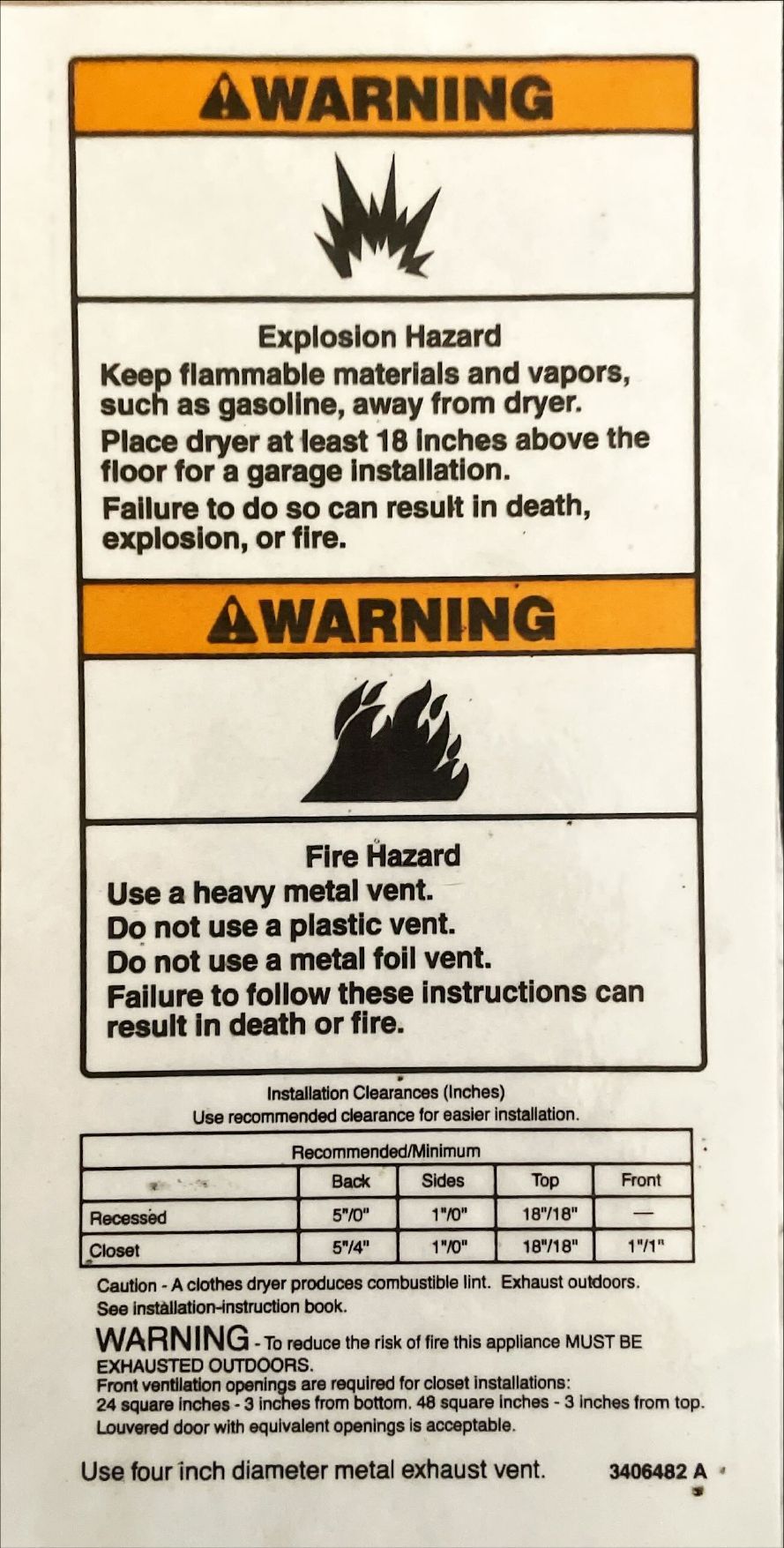

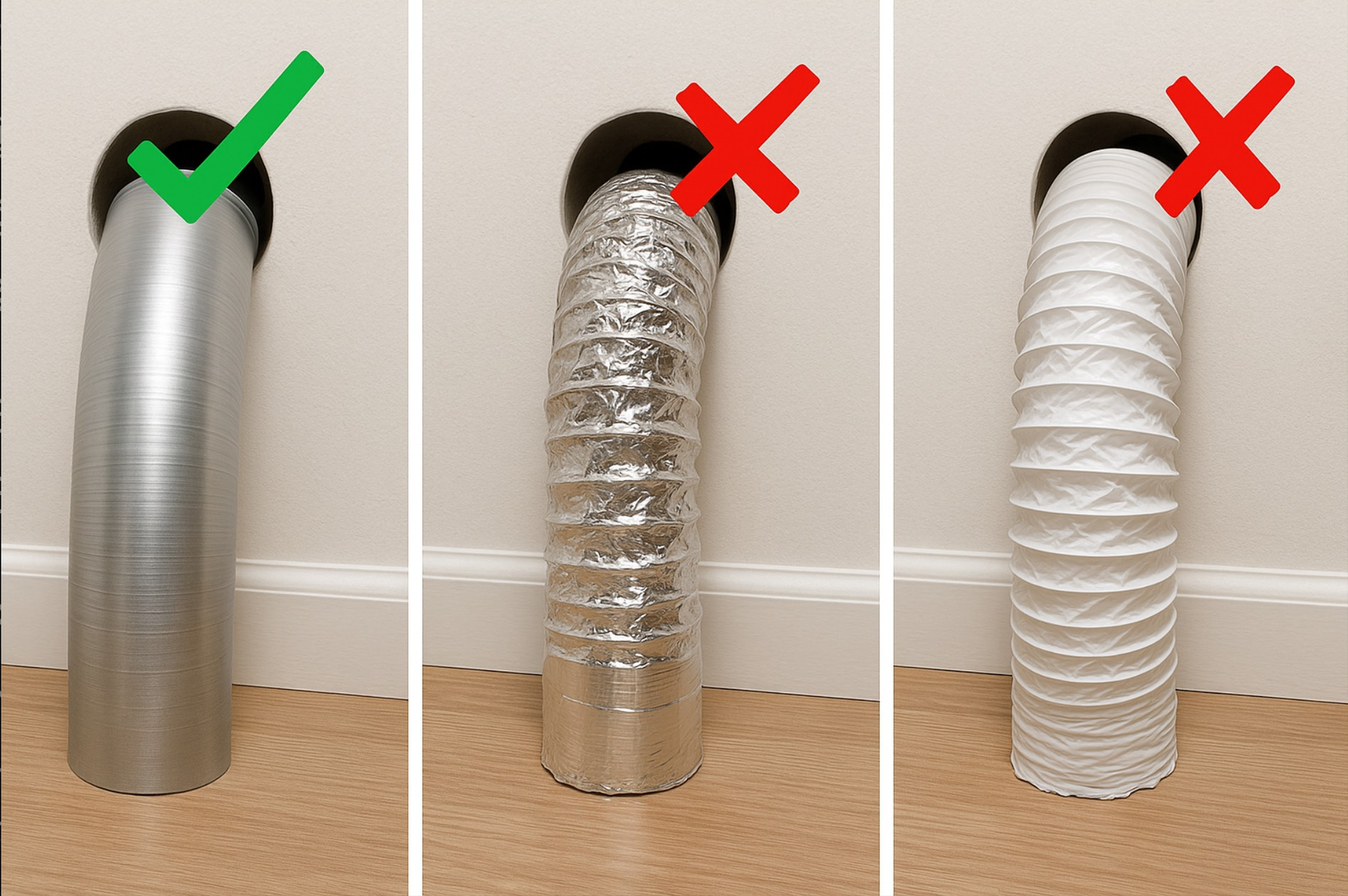

1. Duct Material:

- Must be metal (typically rigid aluminum or galvanized steel).

- Flexible plastic or foil is not allowed for permanent installations.

2. Maximum Duct Length:

- Varies depending on dryer make and model, but IRC generally allows up to 35 feet, with deductions for elbows.

3. Termination:

- Must vent outdoors, not into attics, crawl spaces, or walls.

- Exterior termination must have a backdraft damper (no screen allowed).

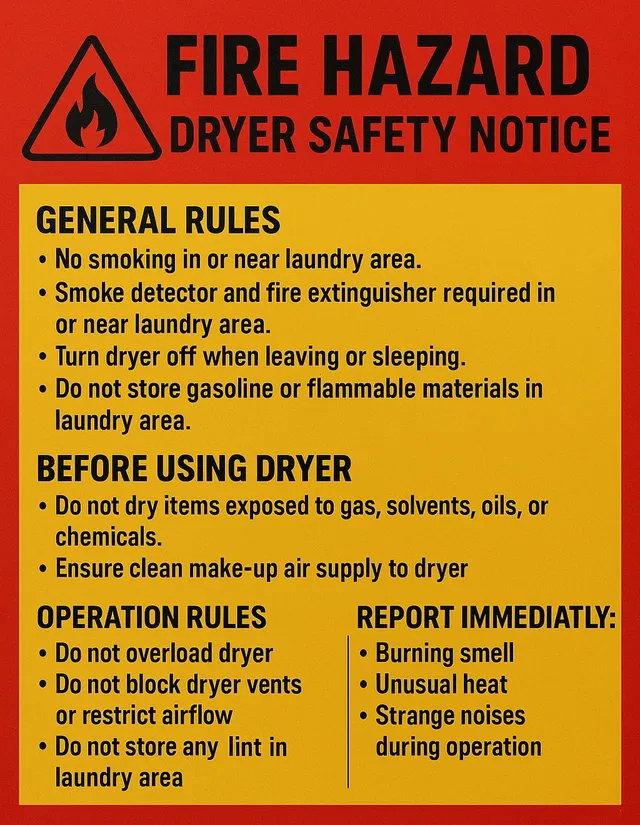

4. Maintenance:

- Regular lint removal is critical.

- Commercial systems may require routine inspection per NFPA 1 or local fire codes.

1. IRC M1502 – Residential (1‑ & 2‑Family)

· Independent duct per dryer; exhaust to outdoors.

· Smooth metal ≥0.0157″ (28 ga), 4″ Ø.

· Supports every 12 ft; screws ≤⅛″ protrusion.

· Max length 35 ft minus 2.5 ft (45°) / 5 ft (90°) credits; label runs >35 ft.

· Transition duct: UL 2158A, ≤8 ft, visible.

· Termination: ≥3 ft from openings, back‑draft damper, NO screens.

· No booster fans; power ventilators must be UL 705.

2. IMC 504 – All Occupancies

· Follows manufacturer instructions first.

· No screens or screws obstructing flow; fire/smoke dampers prohibited.

· Supports every 4 ft; smooth metal ≥0.016″, 4″ Ø.

· Transition duct same as IRC (UL 2158A, ≤8 ft).

· Max length 35 ft with same elbow credits; label >35 ft.

· Make‑up air needed if exhaust >200 CFM (≥100 sq in opening).

3. IMC 504.10 – Commercial Dryers

· Fan motor outside airflow; continuous run or interlock.

· 6″ clearance to combustibles.

· Single UL 2158A transition ≤8 ft, not concealed.

4. IMC 504.11 – Multistory Common Shafts

· Rigid sheet‑steel ≥0.0187″ (26 ga) in fire‑rated shaft; NO offsets.

· Continuous exhaust fan on standby power; alarm on failure.

· 12″×12″ cleanout at shaft base; system serves dryers only.

· No screens at termination.

5. UL / Listing References

· UL 2158A – flexible/transition ducts.

· UL 705 – dryer‑duct power ventilators.

6. Protective Plates

· Steel 0.062″ thick if duct <1¼″ from framing surface; extend 2″ above/below plate.

7. Manufacturer Precedence

· Follow dryer manufacturer instructions where stricter than code.

8. Quick‑Check Table

· Supports: IRC 12 ft IMC 4 ft

· Max base length: 35 ft

· Elbow credits: 45° = 2.5 ft, 90° = 5 ft

· Termination clearance: ≥3 ft from openings, ≥12.5 sq in open area

9. Field Checklist

□ Verify material/size and support spacing.

□ Measure equivalent length; label if >35 ft.

□ Inspect termination (damper, no screen).

□ Check transition duct (UL 2158A, ≤8 ft).

□ Confirm no booster fans.

□ For commercial/multistory: fan placement, continuous run, shaft integrity, alarms.